COMPLETED PRODUCTION PROCESS

Design → Design 3D → Confirmation Shape of 3D print → Structure 3D → Function Scratch Confirmation → Open Mould → Silicone raw material batching → Silicone molding → Silicone grinding → Silicone injection → Silicone Quality Inspection → Finished Product Assembly → Finished Product Testing → Finished Product Quality Inspection → Finished Product → Packaging → finished product for shipment

1. Design

ID department: All appearance of products will be finished here. We have 1 or 2 new design released every month. And more your anyideas will be turned into dramatic drawing by our designers.

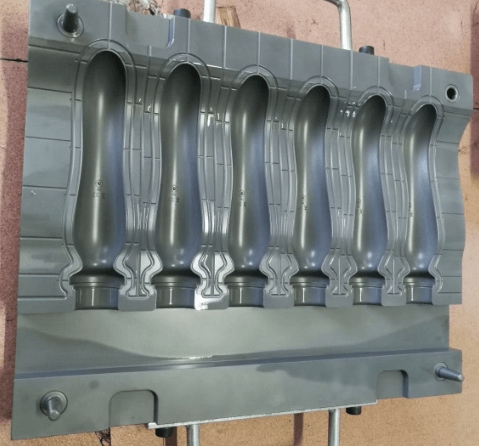

2. Making Mold

R&D department: is responsible for new products information collection, research and developing. Prototype sample will be done here.

Mould department: We have our own molding shop. Precise, fast and high quality are essential requirements for each mold.

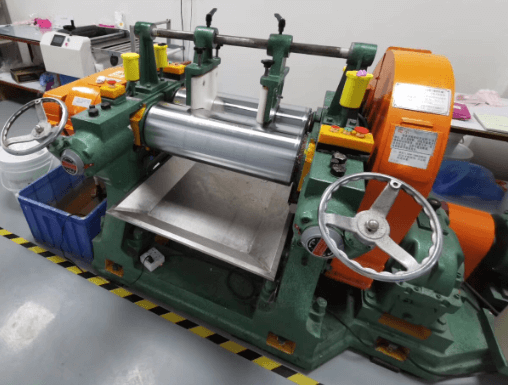

3. SILICONE RAW MATERIAL BATCHING

Mixing with silicone: Adding colorant ,Vulcanizing agent (the curing agent acts as a curing agent) and then mixing at high temperature

Make silicone cut into Strip shape as easily operated on the machine

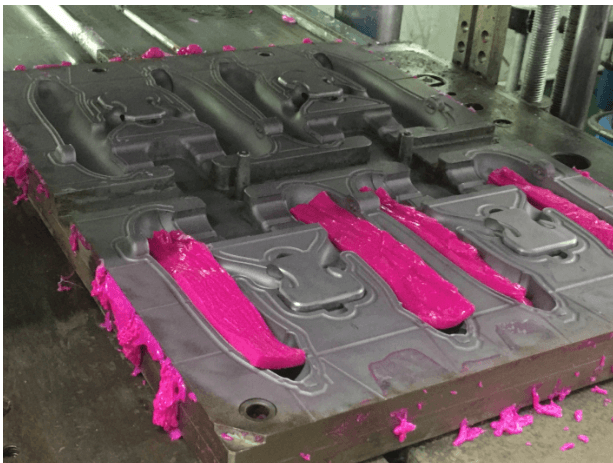

1. SILICONE MOLDING

Weigh Silicone:Weighing Silicone completed weight of silicone

Placing Silicone:Putting Weighed slicone on the mould

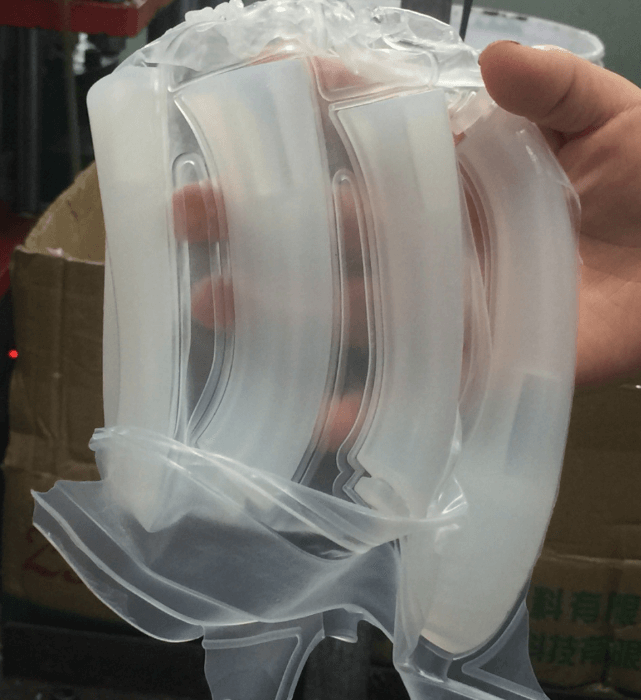

Silicone molding:Silicone sleeves have been made

silicone item completed:Taking the product from the core of mould,Taking the product from the core o mould with air gun

2. PROCESSING ROUGH EDGE

Rough Edge operated by manual work, can not be by machine

Machine Grinding:Rough grinding of products by turbine rotation

Manual Work for Polishing:Small Rough Edge Operated by Manual Work

Cleaning Polished Silicone:After finished Polished Rough edge by Manual Work,It needs to be cleaned

3. Oil Injection:Dry the cleaned silicone item and put it in the automatic oil injection workshop

process: oil injection → baking → finished product

Detecting adhesion of oil injection:Check if the adhesion of oil injection is qualified

4. SILICONE QUALITY INSPECTION

Inspecting defect: poor oil injection, poor grinding,unfinished rough edges, damage of silicone, etc.

5. FINISHED PRODUCT ASSEMBLY

Finished Product Assembly → Finished Product Testing → Finished Product Quality Inspection → Finished Product

6. PACKING